Introduction

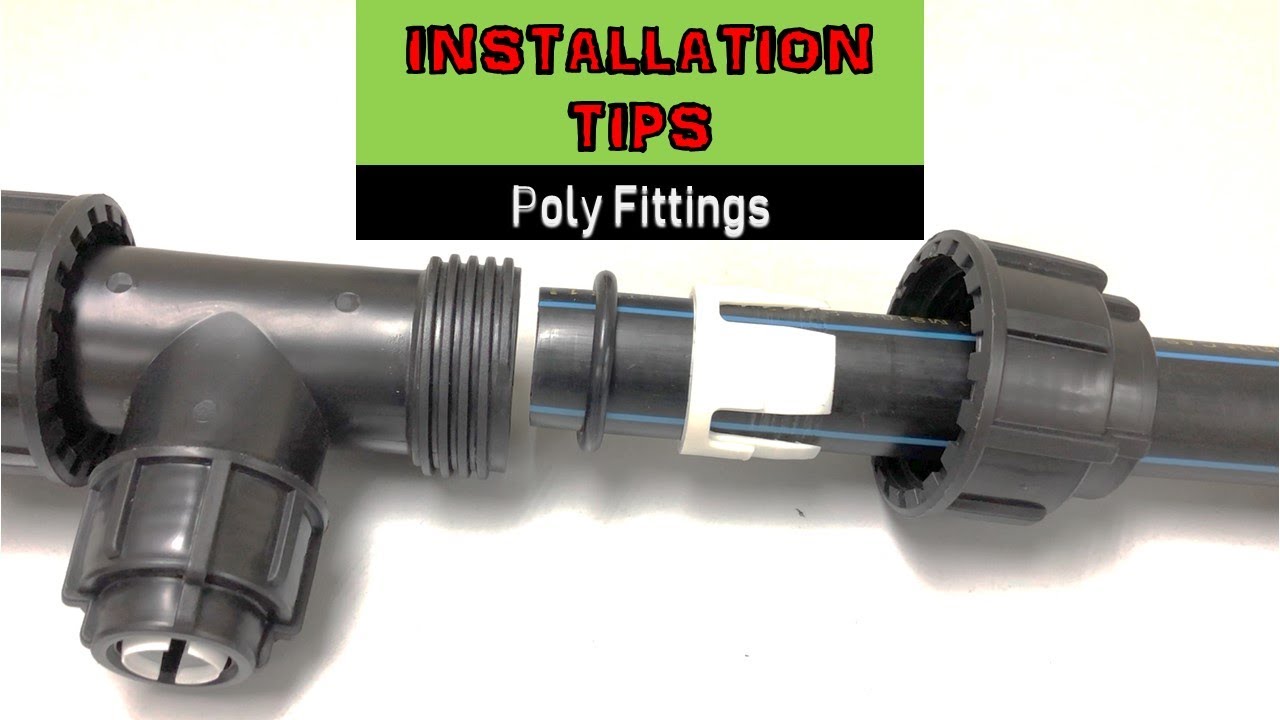

When it comes to plumbing and piping systems, Polyethylene (PE) pipes have become a popular choice due to their durability, flexibility, and resistance to corrosion. However, installing PE pipe fittings can be a daunting task, especially for those who are new to the trade. In this article, we will provide a step-by-step guide on how to install PE pipe fittings, ensuring a safe and efficient process.

Preparation is Key

Before starting the installation process, it’s essencial to prepare the necessary tools and materials. You’ll need a pipe cutter, a drill, a socket wrench, and a set of PE pipe fittings, including adapters, couplers, and tees. Make sure to choose the right type of PE pipe fittings for your specific application, as they come in different sizes and materials. Additionally, it’s a good idea to consult the manufacturer’s instructions and follow any local regulations or codes.

Now, let’s get started with the installation process. First, you’ll need to cut the PE pipe to the desired length using a pipe cutter. Be careful not to damage the pipe or the surrounding area. Next, use a drill to create a hole in the pipe for the fitting, if necessary. Then, apply a small amount of lubricant to the pipe and fitting to ensure a smooth connection.

Installing PE Pipe Fittings

The actual installation process is pretty straighforward. Simply insert the fitting into the pipe, making sure it’s securely connected. Use a socket wrench to tighten the fitting, but be careful not to overtighten, as this can damage the pipe or fitting. It’s also important to note that PE pipe fittings can be connected using a variety of methods, including push-fit, compression, and fusion. Each method has its own advantages and disadvantages, so it’s crucial to choose the right one for your specific application.

For example, push-fit connections are quick and easy to install, but they may not be suitable for high-pressure applications. On the other hand, fusion connections are more secure and durable, but they require specialized equipment and training. So, you gotta do your research and choose the best method for your needs.

Troubleshooting Common Issues

Despite the ease of installation, there are some common issues that can arise when working with PE pipe fittings. One of the most common problems is leaks, which can be caused by a variety of factors, including improper connections, damaged pipes or fittings, or excessive pressure. To troubleshoot leaks, start by inspecting the connections and pipes for any signs of damage or wear. If you find any issues, replace the damaged components and re-tighten the connections.

Another common issue is blockages, which can be caused by debris or sediment in the pipes. To clear blockages, use a pipe cleaner or a drain snake to remove any obstructions. You can also try using a plumbing auger to break up any tough blockages. Just remember to always follow safety guidelines and manufacturer’s instructions when working with plumbing equipment.

Conclusion

In conclusion, installing PE pipe fittings can be a relatively simple process, as long as you follow the proper steps and take the necessary precautions. By choosing the right type of fitting, preparing the necessary tools and materials, and following the manufacturer’s instructions, you can ensure a safe and efficient installation process. Additionally, being aware of common issues and knowing how to troubleshoot them can save you time and money in the long run. So, next time you need to install PE pipe fittings, don’t be afraid to give it a try – with a little practice and patience, you’ll be a pro in no time!